A Photo & Discussion Forum for Wharram Design Enthusiasts

I have a 25 foot umiak trimaran. This funny boat has a steering oar. It is 11 feet long and made from fir heart wood so is very heavy. I trailer this boat about and so need to get the oar out of the way during transit. So i made an attachment point for the oar that uses the figure eight form of 'hinge'. It worked remarkably well on today's sail (crab claw fully up). But i made the wood in the attachment piece parted since i made it a bit too narrow for the load of that heavy oar and the forces exerted as the trimaran takes the wind, but not a real problem. I will just make it a bit more robust. The larger question is this....i used dynex dux line, but because it cannot stretch, it was impossible for me to get the oar snugged in tightly. How do you put tension on these lashings for the rudder and then tie on a stop knot? Does that make any sense? I know i am dealing with something way smaller, but the tension issue is still a problem, i think. At the moment i am contemplating using a softer line that has some stretch, and attempting to stretch it into place before somehow knotting it.

thanks.

thanks.

Views: 1545

Replies to This Discussion

-

Hi,

When we put the rudders on our Tiki 46, I faced the same questions - how to get it tight and tie the knot. Well, we used low stretch dacron braided line and I threaded it in the approved figure 8 manner, and pulled and pulled with each pass and then someone turned the rudder and I pulled some more and repeated that a few times. Then I tied the knot and we sailed for 8 years with no problems. The same line is still in there after over 40,000 miles and it looks new and it is tight. So I guess you just do it and trust the guru. Worked for us. Ann and Nev

-

I used "dinghy line" for my rudder lashing, just a small diameter dacron braid:

Did the same thing as Ann and Nev.

Of course, the rudder and the aft stem are plywood: much less prone to splitting than wood. What are you using? Perhaps if you increase the lashing hole distance from the edge, it will be stronger.

Pictures, show us pictures! I may be assuming the wrong thing. . .There are other ways of lashing such an oar.

-

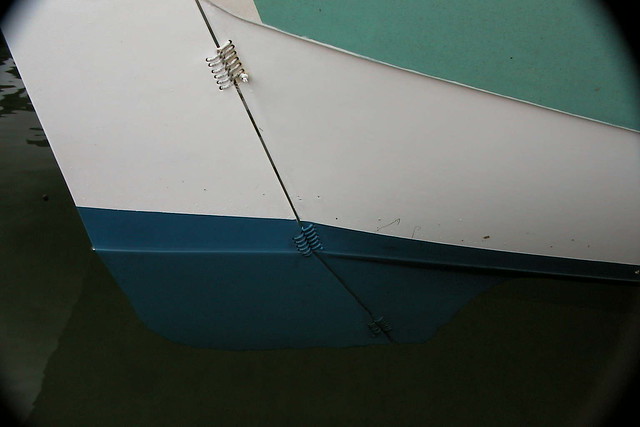

here is picture (i hope this works) of the completed repair to the oar attachment (i can find no reference telling me what the name of this part is....so do i get to name it?)...

- Attachments:

-

Here is a shot of the port steering oar on Glenn Tieman's tama moana, Manurere:

You can see the oar is lashed to the hull side, and rides against a knuckle on its lower end for turning clearance. There is actually a purchase system inside the hull that pulls the lower end tight against the hull, but that also allows the oar to be completely raised out of the water.

Perhaps something similar, meaning using the hull to support the oar.

-

Sorry, but not an option for me. Have to reduce the amount of fiddlefarting around as this is a trailer sailboat with enough of that going on already. Plus it is a cloth covered boat over light bent cedar ribs so there is no there there to easily provide either support from which to pull. I mean it could be done, but no thru-hulls for me thank you. Nice design in the picture though.

And my retention point system works well, the fault was mine for underestimating the forces and shaving the supporting wood too thin. And now i think i have the lashing tight on the new piece. I will see how it takes the pressures now. Marvelously responsive though. Much better than any rudder. The balance on the oar helps but also there is some how a totally different geometry involved that really favors the steering oar over rudder control.

-

Hello Clif

Not quite the same situation but perhaps it will help, our stopper knot was tied twice, once as close as we could get, the second behind the first and tight up against the wood.

We needed to repair the SB rudder as it had developed a crack on the leading edge.

I was a little apprehensive. But as the images show is a relatively straight forward job to reinstall.

The rudder needs to be hung up, loosely with the lashings.

Then braced and centered.

The gap at the bottom is slightly oversized.

Start at the top and work down.

We have a a bit of hardwood shaped like a leg? bone that is used to lever the lashing tight.

Once is as tight as can be but before it is loosened to start the next bit, a wooden spike is "tapped" in to the lashing hole from the other side to keep the tightness while the lashings is looped around and the process is stated again.

The final knot is a made of two knots, the first as tight and as close as possible, but is always a bit slack so lashing is knotted again behind the first, next to the rudder, this seems to make it tight.

As the final photo shows everything hangs nicely with just the right clearance at the bottom.

Images here

Bit I learnt was that perhaps the wooden lever should be a bit longer for easier leverage.

Have plenty of wooded spiles (spikes) handy of a softwood. Don't dive them too hard.

-

Thank you for the pictures. It clears up a lot of questions on technique. I had been using a pair of inuit pliers for tightening. I will add the ramp of the wedge and a second knot. Thanks again. Tres cool boat (from what may be seen in photo's). Ok, adding a bridal to the crab claw today and will also add second knot to new lashings on the steering oar.

clif

-

Glad to be of some help.

Will upload some more images of Tiare as time goes by. Limited as to power to run the Laptop and internet is a bit slow this part of the world.

Cheers

Daniel

-

Hello Dan

will you be in Phuket during January 2011? I plan to do some videoclips with WaveDancer may be we meet once. How's Alex? We'll miss Tiare once she leaves Phuket! Cheers Wave

-

I think there are many ways to achieve the tightness required at that final lashing point. Rotating the rudder from side to side helps take out any unseen slack. Using vise grips, or a stick through a slip knot to really reef on the line helps too. Now for the final treading and the knot. Pull the line as tight as you can and then some, then perpendicularly skewer the line with a pin, sew needle or other such item that is appropriate to the line diameter. Tie the knot, caulk or epoxy the line into the threading holes and when all done remove the pin. Tight as can be! Hope this helps.

-

WaveDancer said:Hello Dan

will you be in Phuket during January 2011? I plan to do some videoclips with WaveDancer may be we meet once. How's Alex? We'll miss Tiare once she leaves Phuket! Cheers Wave

Just anchored in Perhentians East Coast Malay. Hope to start the run down to Singapore then up to Phuket arriving mid Nov'. Then up to the islands near Myanmar. Probably leave Phuket area around March 2011 back around to East coast Thailand as I have a 3 week contract near Bangkok, after that would like to make it to Palawan in Philippines. But thats a bit far out to plan.

Would love to catch up with you!

last I heard Alex is fine, has done a few charters with Full Steam.

Cheers

CooperDan

-

But wich kind of knot do you tie after the last hole? Is this really a stopperknot?

© 2025 Created by Budget Boater.

Powered by

![]()